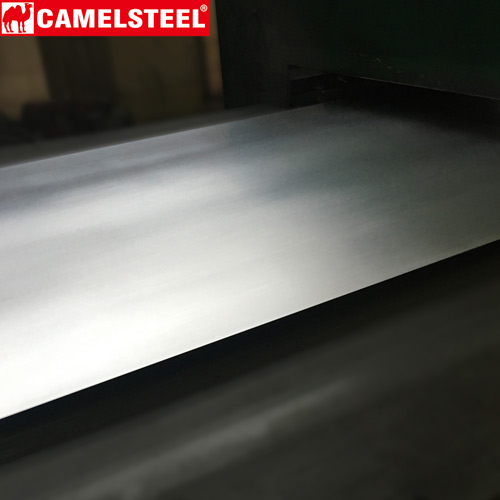

GI Sheet Definitions.

In order to prevent the steel’s surface from corroding and prelong its service life, people coat the zinc on the surface of the steel’s surface, and the steel becomes zinc coated steel.

Classifications and uses.

The production and process methods could be classified as the follows.

(1) Hot-dip gi sheet. People put it into the melted zinc pot and make its surface have some zinc. Currently, people often use the continuous zinc coating to produce it, Which means people often put the steel rolls into the molten zinc pot continuously.

(2) Alloy galvanized sheets. It is made by hot dipping, but it is heated to 500 degrees after out of the zinc pot. Then it produces the alloy film immediately. It has great adherence and weldability.

(3) Electric steel sheet. It is very useful by electrochemical plating. But its cladding material is very thin, and the corrosion resistance is worse than that of the hot dipped zinc coated steel.

(4) Single galvanized steel and two-sided galvanized steel. Single galvanized steel is only galvanize one side of the steel. Compared to the two-side galvanized steel, it is better to weld, coat, rust prevent and process.

(5) Alloy and compound galvanized steels. It is made from zinc and other metals, such as lead, and compound steel. It has great anti-corrosion performance and coating performance.

There are also color galvanized steel, print coated galvanized steel and PVC fold galvanized steel. But the hot-dip galvanizing steel is the most common one.

Galvanized steels could be applied into building roof, out wall, structure and extrude.