Based on CAMELSTEEL years of production experience of hot dipped galvanized steel sheet, it can be found that the skin passed of galvanized steel sheet can greatly improve its surface quality and performance. The specific roles are as follows:

(1) Improve the surface planeness of galvanized sheet

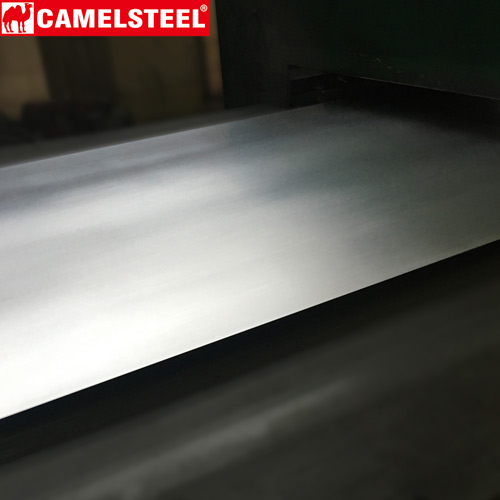

After skin passed, the surface planeness of zinc galvanized sheet will be improved, with shape wave removed partially.Also,the slag particle and other scraggly punctate substance evened out, thus the surface looks sooth and flat.

(2) Adjust the surface roughness of zinc galvanized sheet

It can adjust the uneven the surface roughness of zinc galvanized tile and unify it within a certain range via controlling the surface roughness of working roll of temper mill.

(3) Improve the surface glossiness of zinc galvanized metal sheet As for small/zero spangle products, the skin passed can ensure that the surface of galvanized steel sheet has a more even and unified glossiness. The spangles salient points due to crystallization of big spangles and different glossiness can be unified, thus the spangles can be easily covered during coating.

(4) Improve the process performance of galvanized steel sheet

Via skin passed, the yield platform of galvanized sheet can disappear or be not obvious, which can avoid generating metal slip lines during production.