Zinc is a blue white metal which is of middle malleability.

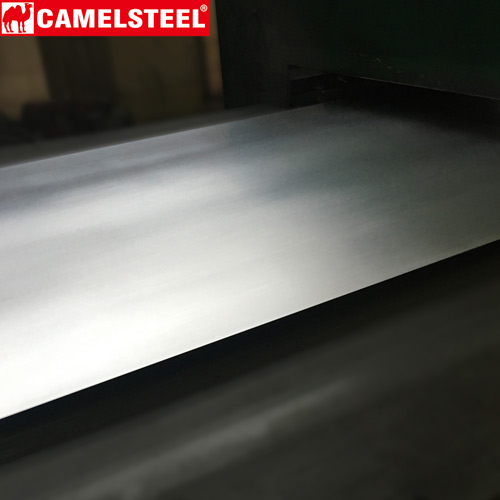

Under indoor temperature, zinc dose not change in dry air. In wet air, the zinc surface sees a layer of compact zinc carbonate film which can prevent the inner of zinc from being corroded. Relying on the advantage, zinc is galvanized on the surface of steel sheet to avoid corrosion.

The service time of steel plate will greatly lengthened after it is galvanized. If the zinc layer in the steel plate is not broken, zinc can prevent corrosive medium being contacted with the steel plate surface. However, if the galvanized layer is damaged, irons in some special parts come out of the surface, when zinc and iron form microbattery during the corrosive process as zinc is more active than iron considering chemical property.

Zinc is the positive pole of microbattery and is easy to be dissolved during corrosion. Iron is the negative pole which is protected. Therefore, hot dipped galvanized coil vessel will not suffer rust even some parts see exposed iron. On that account, hot dipped galvanized coil enjoys good anti-corrosion performance.

Leave A Comment