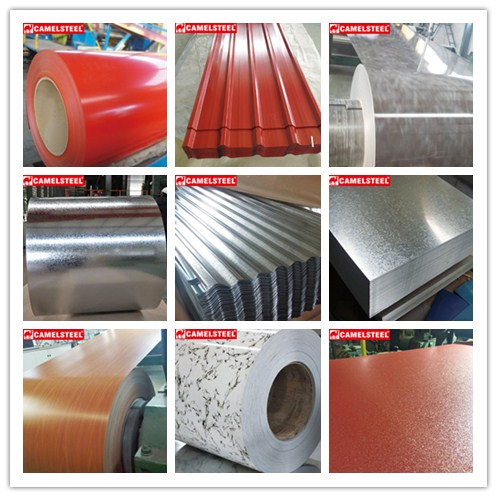

As the composite materials that widely used in construction, home appliances, transportation and other industries, color coated steel coil has not only the mechanical strength and easy molding of metal, but also the decorative characteristic and corrosion resistance of organic coating. In general, the level of corrosion resistance is closely related to the color coated steel coil coating thickness. Under normal circumstances, the corrosion resistance rise with the increases of color coated steel coil coating thickness.

The color coated steel coil coating thickness will directly affect its processing and use performance. For CAMELSTEEL, it is important to accurately measure and strictly control the coating thickness of the color coated steel coil during the production of color coated plates. If the coating is too thin, it is easy to scratch the coating and then affect the decorative and corrosion resistance of color coated steel coil.

For the too thin coating, even if it can ensure the coating is not destroyed during processing, its aging resistance and corrosion resistance will be greatly reduced in the use process. However, too thick coating will result in an increase in the production cost of color coated plates, and this is also a waste of product quality surplus.

Leave A Comment