The surface coating of hot dipped Galvalume Sheet is 55 % of Al-Zn alloy.

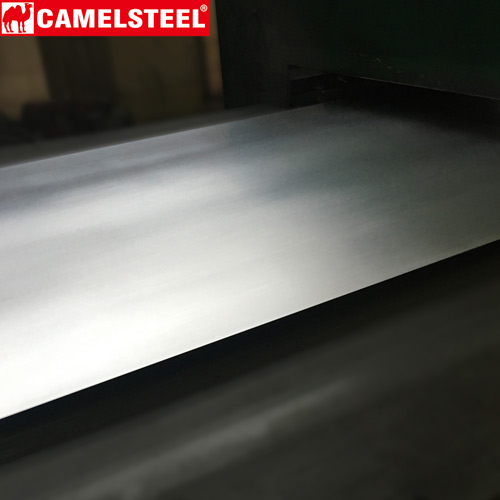

Hot Dipped Galvalume Sheet has smooth, flat and gorgeous patterns on the surface, and its base color is silver. The special coating structure made it has good anti-corrosion property. The normal working life of Galvalume Sheet can up to 25 a. It has good heat resisting property and can be used in high temperature condition of 315 ℃. The coating and film has good adhesive force and processability, which can stamp, cut and weld. Surface conductivity of Galvalume Steel Sheet is good.

The coating consists of 55 % of aluminums, 43.4 % of zinc and 1.6 % of silicon based on weight rate. The production technology of Galvalume Sheet is similar to galvanized steel and aluminum plate, it is continuous melting coating technology. 55 % of Al-Zn alloy coating Galvalume Steel Sheet has better anti-corrosion property, compared with same-thickness galvanized steel under the same environment. Besides, prepainted products have better adhesive force and flexibility.

CAMELSTEEL consistently carry out the policy of “Customer first, employees of the second, third shareholders” and the tenet of “Treat people with sincerity, start business with trustiness”. We insist brand building of main line, market demand oriented, not afraid to innovate, keep providing the first-class service and quality products for customers indeed.