描述

Galvalume Metal Coil Specification

| Name | GI steel coil | GL steel coil/Anti-Finger |

| Standard | GB/T-2518

JIS G3302 EN 10142/10427 ASTM A653 |

GB/T-14798

JIS G3321 EN 10215 ASTM 792 |

| Grade | SGCC

DX51D+Z |

SGLCC

DX51D+AZ |

| Thickness | 0.12-2.0 mm (±0.02 mm) | 0.16-0.7 mm (±0.02 mm) |

| Width | 30-1250 mm (±2 mm) | |

| Length | Coil or as Customer’s requirement | |

| Zinc/Aluzinc coating | Zn 40 g/sm-275 g/sm | Alu-zinc 40-150 g/sm |

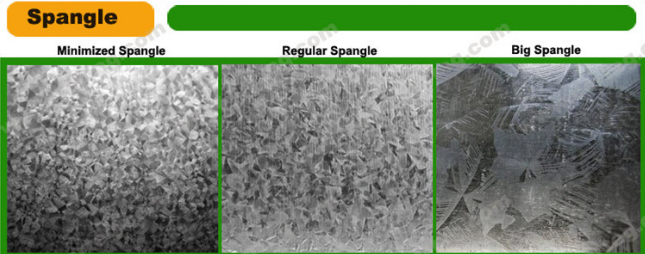

| Spangle | Zero/ Mini/ Regular/ Big | Regular |

| Coil weight | 3-5 tons or As your requirement | |

| Hardness | CQ/ FH/ As your requirement (G 300-G 550) | |

| Surface Treatment | Anti-Finger printing, Chromated, oiled/ non-oiled | |

| Certification | ISO9000, BV, SGS, etc. | |

| Application | Structural use, roofing, corrugated roofing, commercial use, household appliance, industry, etc. | |

Galvalume Metal Coil Packaging & Delivery

- Packaging Details :

- Delivery Time : 7-30 days after deposit.

Spangle:

Galvalume Steel Production Line Can Produce ZERO Spangle, Small Spangle And Common Spangle etc. Thickness From 0.125 mm To 4.5 mm. And Width From 500 mm To 1250 mm. Zinc Coating From 40 – 275 g/m2. Surface Passivation And Oil-Coating Can Be Performed.

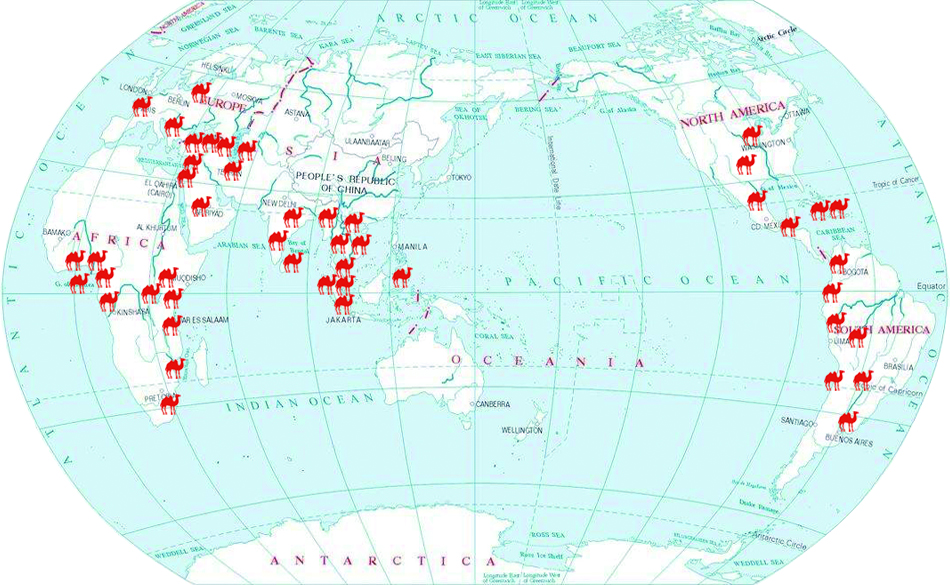

Customers

Our products sell pretty well not only in domestic market, but also prevails in Europe, such as southeast Asia, Russia, Ukraine, the United States, Canada, Brazil, Colombia and other countries and regions, which has earned the customers trust & compliment and successfully transitioned from home to abroad.

Experimental Test

Our strictly control the quality on each steps of production. Including inspection on raw materials entry, product’s color analysis during production, T-bend test, impact test, salt-spray test, tensile test and packaging testing on exported products, which ensures its integrated performance such as corrosion resistance, coating stickiness etc. and the safety of transportation.